Ring Joint Gasket

Features:

RTJ Rings, also called Ring Joint, are machined or forged rings that are used as sealing gaskets in flanges with housing for the same.

Ring joint gaskets are solid metal gaskets and are used with stand high pressure and temperature, and they are employed where corrosive agents are presented. It is recommended that the gasket material be softer than the mating flanges. The small sealing area and high contact pressure results in excellent sealability. Our ring type gaskets are manufactured according to ASME B16.20 (2007)standards and to API specifcation 6A and17B. Careful control of all manufacturing processes ensures correct surface hardness to give a good seal without damaging flange connections.

Advantages

• Secure sealing action through metal-tometal contact for reliable sealing in high pressure applications.

• They are used in the oil field on drilling and completion equipment and in downstream refinery applications. Ring type joints are also commonly used on extremely high-pressure valves and pipework assemblies, along with some high integrity pressure vessel joints.

Properties And Application

The metallic ring joint gaskets are manufactured according to the API 6A and ASME B16.20 standards for opplicotion at elevoted tempe「otu「es and pressures. The small sealing area with high contact pressure results in great reliability. The contact surfaces of the gaskets and Honge should be cceefully processed. Some types of ring-joints are pressure activated, that means, higher the pressure better the sealability.

Advantages

The metal ring joint gaskets have been designed to withstand exceptionally high assembly loads over a small area, thus producing high seoting stresses.

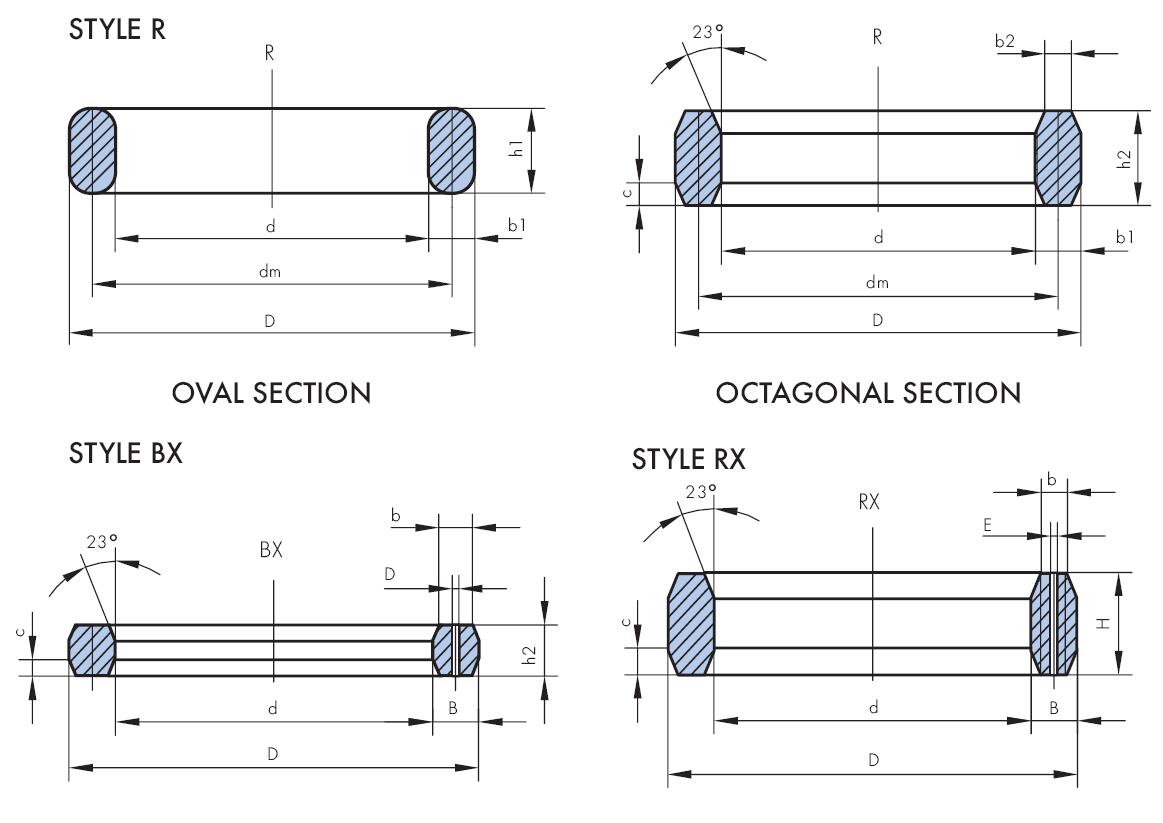

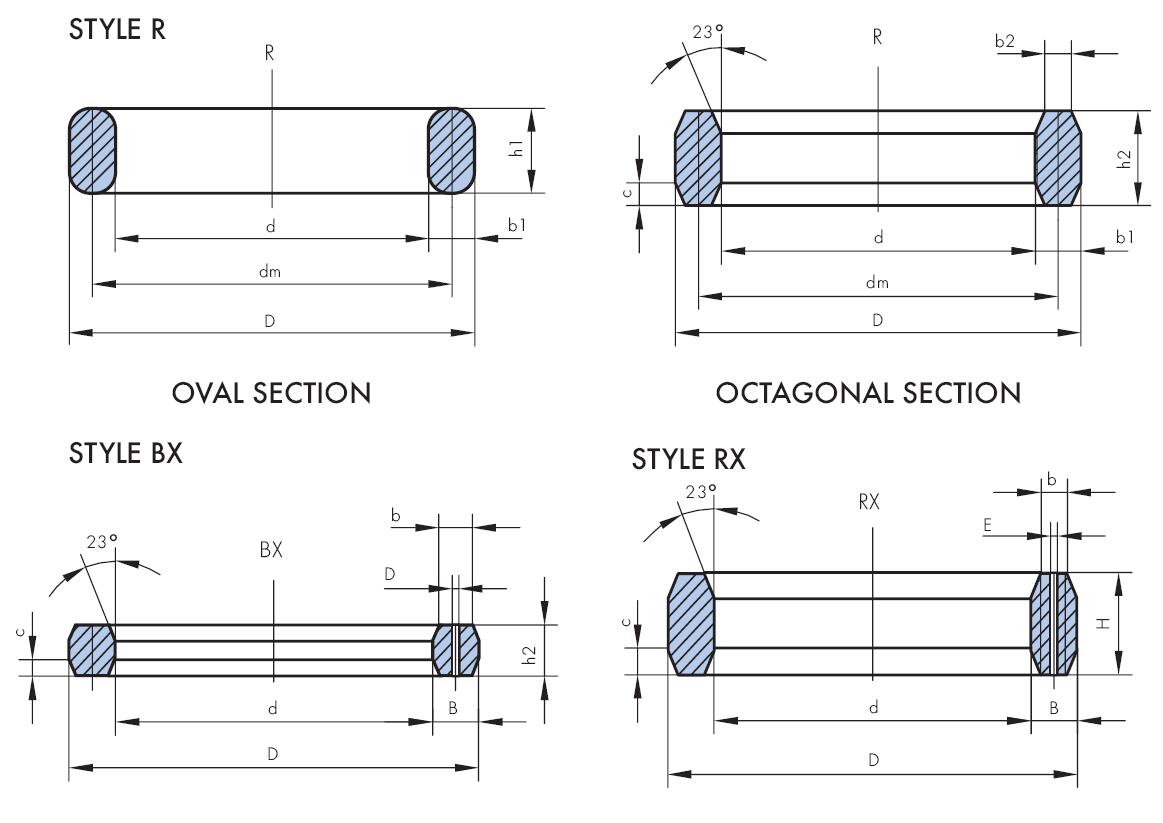

Shape And Construction

The ring joint gaskets are produced in several shapes and sizes to meet the most demanding applications.

Standrand Materials: Soft Iron/SS304/SS316/Inconel625

Dimensions

(STANDARDS FOR RING JOINT GASKETS USED WITH FLANGES)

| Ring Joints Gaskets Style |

Ring Joints Gaskets Standard |

Flange Standard |

| R |

ASME B 16.20

API 6A |

ASME B 16.5

ASME B 16.47 series A |

| RX |

ASME B 16.20

API 6A |

API 6B |

| BX |

API 6A |

API 6BX |