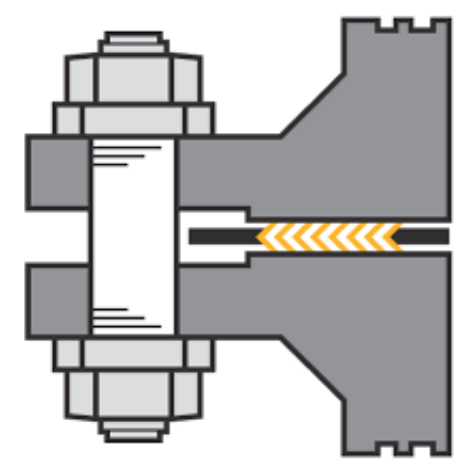

Spiral Wound Gasket

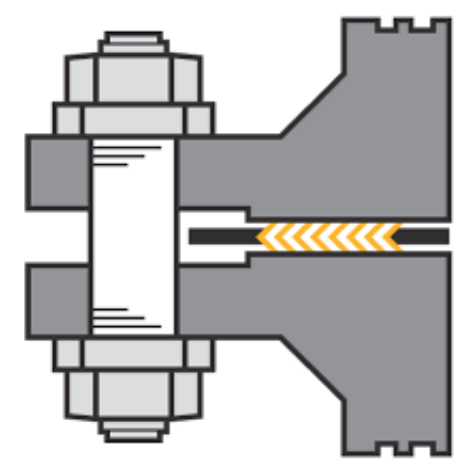

Spiral wound gaskets are the gaskets made of "V" or "W" shaped stainless steel strips and other flexible materials such as graphite, asbestos, Teflon and non-asbestos, which are fixed by spot welding for flanged joints, exchangers heat, boiler orifices, well applications.

Application

Static sealing element of pipe, valve, pump, thermal exchange, condensing tower, plain hole and man hole of flange, etc.

Industry: petrochemical, mechanical manufactory, power station, metallurgy, shipbuilding, medical and pharmaceutical nuclear power station and navigation, etc.

Spiral Wound Gaskets can be used to seal fluid pressure up to 250 bar cryoprnices temperature as low as -200°C and up to elevated temperature of 1000°C.

| STYLE | Name | Section Plane |

| GHS-A | Basic type |  |

| GHS-B | With inner ring |  |

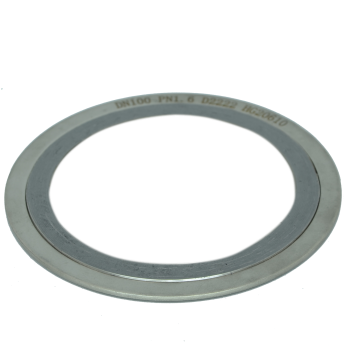

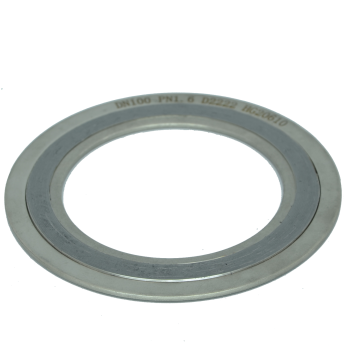

| GHS-C | With outer ring |  |

| GHS-D | With inner &outer ring |  |

-

Spiral Wound Gasket Dimensions per

ASME B16.20 for ASME B16.5 Flanges

ASME B16.20 for ASME B16.47 Series A

ASME B16.20 for ASME B16.47 Series B

Style 911 for Male and Female ASME B16.5 Flanges

| RING MATERIAL | FILLER MATERIAL |

| S 1400 | Asbestos |

| SS 304 | Graphite |

| SS 316 | PTFE |

| SS 316L | Non-Asbestos Fiber |

| SS 310S | Ceramic Fiber |

| SS 321 | |

| SS 320S17 | |

| SS 304L | |

Technical Data:

| RING MATERIAL |

FILLER MATERIAL |

TOP-TEMPERATURE |

| S 1400 |

Asbestos |

|

| SS 304 |

Graphite |

650 ℃ |

| SS 316L |

PTFE |

200 ℃ |

| Inconel |

Non-Asbestos Fiber |

500 ℃ |

Remark: Graphite filler material used for oxidizing media ≤ 450℃

Gasket Size Limit Deviation (mm)

| Inner ring ID |

NPS≤3" |

±0.75 |

Sealing Element

ID |

NPS1/2"~8" |

±0.4 |

| NPS 4"~24" |

±1.5 |

NPS10"~36" |

±0.75 |

| NPS≥28" |

±3.0 |

NPS>36" |

±1.3 |

| Outer ring OD |

±0.75 |

Sealing Element

OD |

NPS1/2"~8" |

±0.75 |

Inner ring/Outer ring

Thickness |

3.0~3.3 |

NPS 8"~24" |

+1.5

-0.75 |

| Gasket Thickness |

±0.13 |

NPS>24" |

±1.5 |